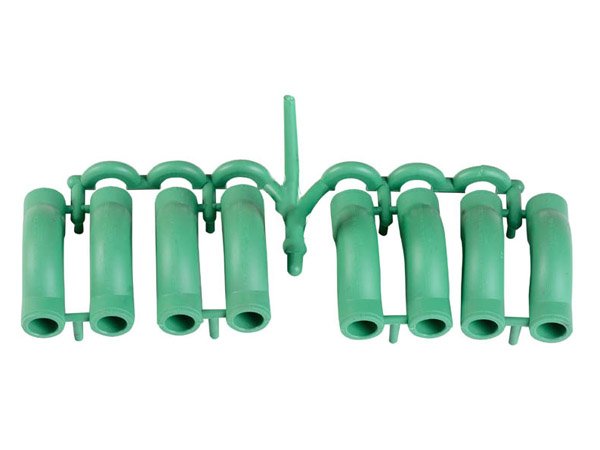

PPR pipe joint mold

Tsmold, is a professional design, research and development and manufacturing as one of the injection mold enterprises. We have special experience in producing custom moulds, specializing in pipe fitting moulds. Such as pipe fitting mould, including sanitary and drainage system, drinking water supply, roof drainage, agricultural irrigation, and gas supply of PVC, PPR, PP, HDPE, ABS, PPSU and other materials. Because we think that only concentration can make more professional and provide customers with the most competitive mold.

1.Basic characteristics of PVC materials

The expanding mold has the advantages of high dimensional accuracy and stable performance, and has achieved ideal application effect in actual production

Features:

1. High pressure CPVC pipe fitting mold.

2. UPVC pipe fitting mould for drainage

3. PVC bend fitting mould (foldable core with pressure water supply).

Advantages:

1. Hot runner

2. Longer service life

3. With the hot runner system, the molding cycle can be shortened by 30% and the production efficiency can be improved;

2.Product specification for Self welding PPR pipe fitting mold

Self welding PPR pipe fitting mold | |

Mould Name | Headlamp mold |

Product Description | High pressure PVC pipe fittings mold |

Mould Cavity | 2 cavities |

Mould size | According the sample size |

Mould Material | Germany 2316 |

Mould Life | 1000,000 shots |

Runner System | Hot runner |

Ejection system | Hydraulic Cylinder |

Mould Running | Automatically |

Design software | UG,PROE,CAD,etc. |

Plastic material | PVC /CPVC/UPVC |

Process Machine | CNC, High Speed Carve, EDM, Wire Cut, Driller, Grinder, fly cutter,etc. |

Package | Wooden Case/pallet |

3. Product application

|  |

| Home decoration system | Building engineering piping system |

|  |

| Municipal engineering pipeline system | Agricultural irrigation pipeline system |

4. Production details

The expanding mold has the advantages of high dimensional accuracy and stable performance, and has achieved ideal application effect in actual production

|  |

| |

5. Production process and inspection

B、Technical department according to customer requirements and project mold production standards, formulate design plans, mapping products on the product modeling design, on time to complete the design task.

C、After the mold design is confirmed, the technical department will import the data into the BOM list, and each department will start the operation according to the mold manufacturing process

D、After sending the mold product samples, the Marketing Department shall inform the project department to arrange the modification or the mold shipment notice after receiving the written notice of modification or confirmation of qualification from the customer. (in foreign countries, the foreign trade staff shall inform the project)

6. Inspection tools

|

|

Ultrasonic testing is the use of ultrasound can penetrate into the depths of the metal materials, and consists of a section into another section, on the edge of the interface reflection characteristics of flaws, a method to check the parts when the ultrasonic beam from the surface by the probe through the metal parts inside, encountered defects with parts respectively when bottom reflection wave, formation of pulse waveform on the screen, according to the pulse waveform to judge the defect position and size. | Richter hardness tester is a kind of testing equipment, its basic principle is that the impact body with a certain mass under the action of a certain test force impinged on the sample surface, measuring the impact body from the sample surface 1mm impact speed and rebound speed, using the electromagnetic principle, induction and speed proportional to the voltage. |

|

|

Coordinate Measuring Machine, CMM, it is to refer to in thethree-dimensional measurable space range, according to thepoint data returned by the Measuring head system, throughthe three Coordinate software system to calculate various kindsof geometry, size and other Measuring ability of theinstrument, also known as three dimensional, three CoordinateMeasuring Machine, three Coordinate Measuring instrument. | Rockwell hardness test method is characterized bysimple operation, rapid measurement, and can beread directly from the dial gauge or opticalprojection screen or display screen. It is one of thethree most commonly used hardness tests, alongwith Brinell and Vickers hardness test. |

7. Mould manufacturing standards

Mainly divided into:

1. Mold external specifications

2. Ejection reset, core insertion and removal, and component removal

3. Cooling

4. General pouring system (excluding hot runner)

5. Hot runner system

6. Forming part and parting surface exhaust groove

7. Packaging

8. Our main processing equipment

Main processing equipment | specifications | Quantity(set) |

High Speed 5axis CNC machine | 3200*1800*1500 5 axis | 2 |

High Speed 3axis CNC machine | 2500*1600*1600 3 axis | 3 |

1600*1200*1000 3 axis | 3 | |

1600*1200*1000 3 axis | 3 | |

1400*700*600 3 axis | 3 | |

1400*700*600 3 axis | 3 | |

Spotting machine | 1600*1000*1000 | 1 |

1600*1000*1000 | 1 | |

1800*1200*1000 | 1 | |

2300*1500*1500 | 1 | |

3200*1800*1500 5 axis | 1 | |

EDM machine | 2000*1500*1200 double | 3 |

1800*1200*1000 double | 1 | |

1500*1000*500 double | 1 | |

1500*800*600 double | 1 | |

Spotting machine | 300T | 1 |

500T | 2 |

9. Our working environment

|  |

|  |

|  |

|  |

10.Product Qualification of mould

| Our Factory | |

| |

| Processing equipment | |

|  |

|  |

|  |

| Warehouse | Shipping |

|  |

11.Delivery,Shipping and Serving of mould

What about the delivery time?

60 days for samples, 80 working days for mass production. Depends on qty/sizes.

We can produce the mould according to your sample.

The payment term

TT /LC /West Union /PayPal/cash.

Package

Standard wooden case

Shipping

Sea/ Air/ UPS/DHL/TNT/FedEx

12.FAQ

Q:1. What percentage of die exits are there?

A:80% of our molds are exported to Canada, Europe, Japan and Mexico, Russia, Southeast Asia, Africa, the Middle East and other countries.

Q;2. Can we do the inlay?

A;Yes, we can, and we are good at inlaying. We have provided good service to some of our customers and gained more experience in inserting molds.

Q;3. Can we make multi cavity mold?

A;Yes, we made some mould with 4, 8, 12, 16, 32 cavities.

Q;4. Do you want to make prototype mold?

A;Yes, we also make some prototype molds for customers if they need.

Q;5. How to pack the mold?

A;After the mold is finished, we will pack the mold with plastic film and put it into the sterilized wooden box. Accessories: necessary accessories such as ring bolt, air cylinder, mold locking sleeve, etc.